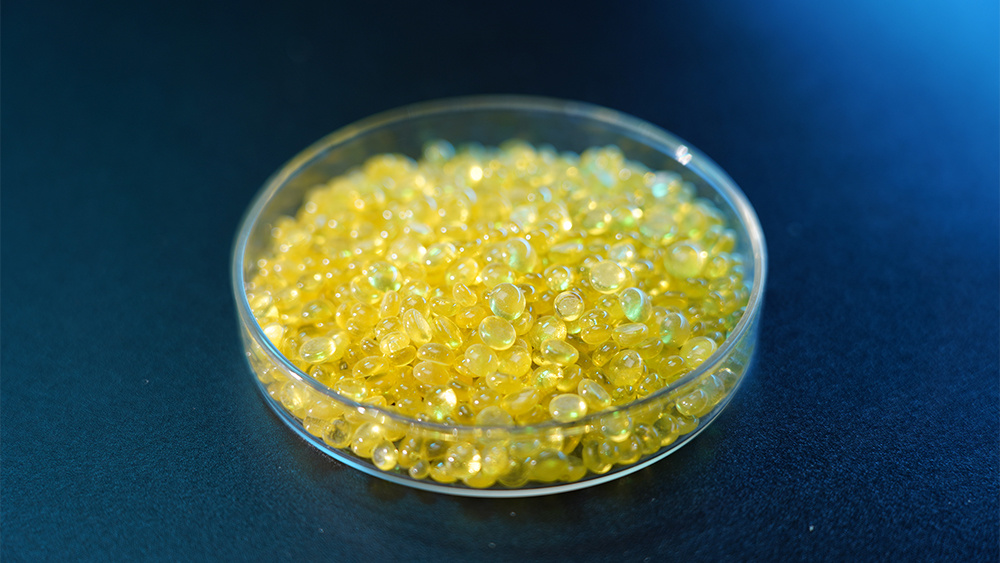

Furan Resin

-

Furan ResinAs one of the world's largest furan resin manufacturer, Shengquan has long been committed to the development and application research of furan resin, and constantly improves its propertie.

Furan ResinAs one of the world's largest furan resin manufacturer, Shengquan has long been committed to the development and application research of furan resin, and constantly improves its propertie.

-

Alkaline Phenolic Resin

Alkaline Phenolic ResinNo bake phenolic resin process, also known as the α-set method, is a process of mixing sand with the alkaline phenolic resin and organic ester hardener to make mould and core and get hardened at room temperature.

-

Phenolic urethane no-bake resin

Phenolic urethane no-bake resinThis resin is developed for the fast and mass production of no-bake sand moulding line. The binder system consists of three parts, i.e., benzyl ether phenolic resin solution (part I), polyisocyanate solution (part II) and catalyst (part III).

-

Cold Box Resin

Cold Box ResinThe amine cold box resin sand process is the leading process of cold box making.

-

CO2 Cured Alkaline Phenolic Resin

CO2 Cured Alkaline Phenolic ResinCO2 cured alkaline phenolic resin process, also known as β-set method, is a process of mixing sand and resin for moulding and core making, blowing in CO2 for hardening.

-

Hot Box Resin

Hot Box ResinShengquan Hot Box Resin is a binder that cures under heating, which used for mass production of efficient core making.

-

Phenolic Resin for RCS

Phenolic Resin for RCSShengquan has devoted itself to the development and research of phenolic resin for RCS for a long time. Thanks to constantly improved performances of phenolic resin, RCS can be widely used in various casting fields.

-

Organic Warm Box Resin

Organic Warm Box ResinShengquan organic warm box resin is a new type of binder with high strength, low energy consumption, good collapsibility and environment friendly, especially suitable for high-efficiency core making of aluminum castings.

-

Inorganic No-bake Binder

Inorganic No-bake BinderShengquan has conducted in-depth research, by making use of special processes and materials, we have developed the inorganic no-bake binders to overcome disadvantages of traditional inorganic binders.

-

Inorganic Warm Box Binder

Inorganic Warm Box BinderShengquan inorganic warm box binder is a non-emission silicate binder system, which consists of liquid binder and powder additives.

-

Coating

CoatingFoundry coating is an important material during casting production, especially for sand casting process.

-

Filter

FilterIt is an effective solution to improve the surface and internal quality of castings through using filter.

-

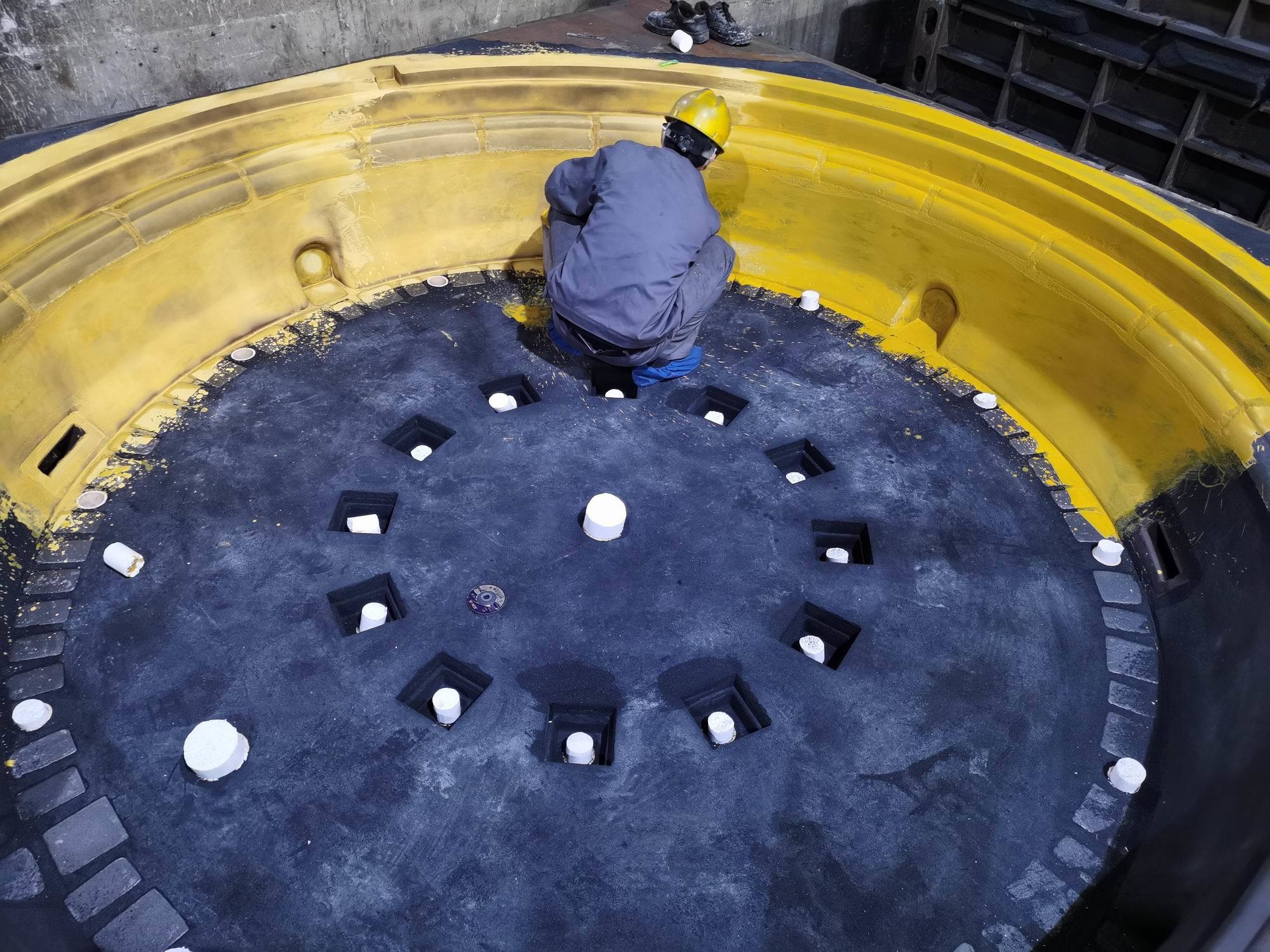

Riser

RiserThe exothermic-insulating riser sleeves burn and generate heat through the exothermic agent after contacting the molten metal.

-

Auxiliary Material

Auxiliary MaterialThe auxiliary materials include: release agent, binding agent, cleaning agent, mould sealing paste, mould strip, anti-veining additives, etc.

-

Melting Material

Melting MaterialAs an influential manufacturer of smelting alloy material for casting in China, Inner Mongolia Shengquan Keliyuan New Material Technology Co., Ltd.

-

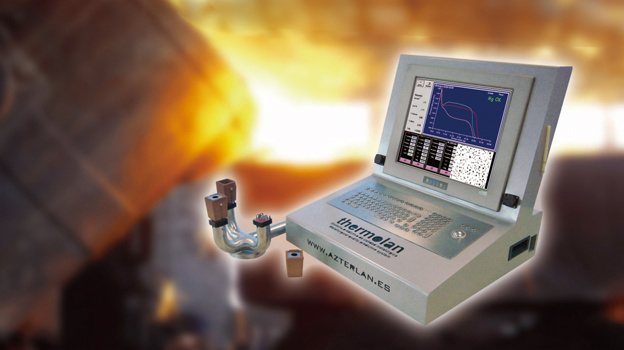

Equipment

EquipmentShengquan has developed an automatic controller for curing agents, a centralized resin/curing material supply system,

-

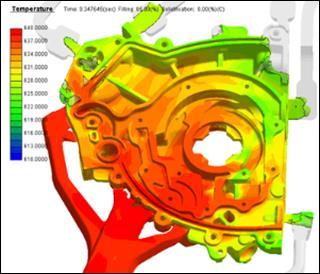

Anycasting Simulation Analysis Software

Anycasting Simulation Analysis SoftwareBased on years of experience in foundry engineering and software development technology, AnyCasting software has become one of the most advanced and experienced casting simulation analysis software.